about qc water

Charlotte Water knows the importance of innovating for the future of our city, today. QC Water was born from a vision of sustainable and responsible water usage, inspired by forward-thinking communities worldwide that are using breakthrough technology to address critical water needs while creating opportunities for responsible recreational and commercial uses.

Charlotte Water, in partnership with Xylem, has invested in cutting-edge purification technology to bring QC Water to life—transforming what was once considered waste into a premium resource that exceeds all drinking water standards. This is just the beginning of what's possible when innovation meets necessity.

Our Unique Process

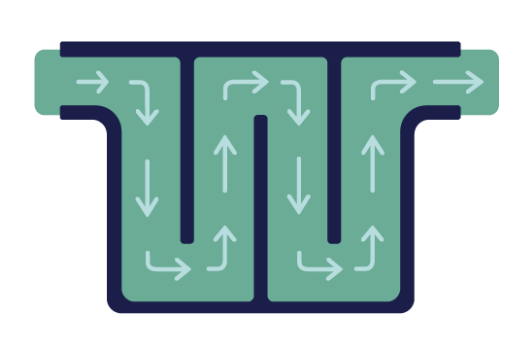

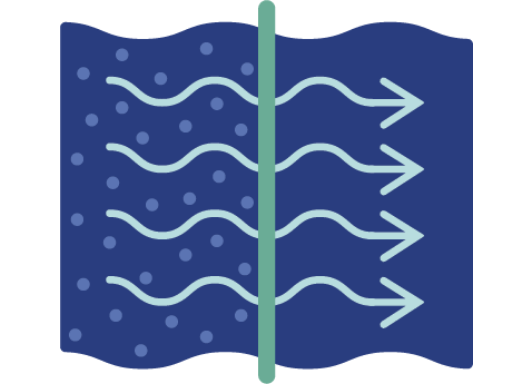

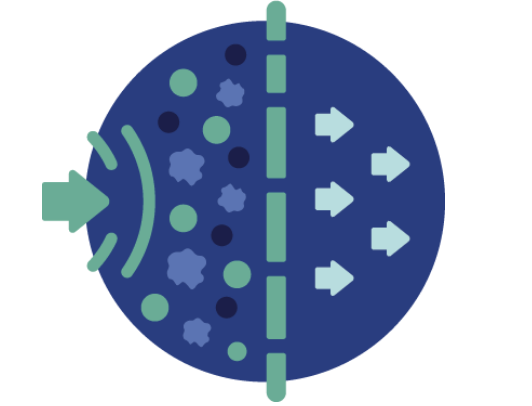

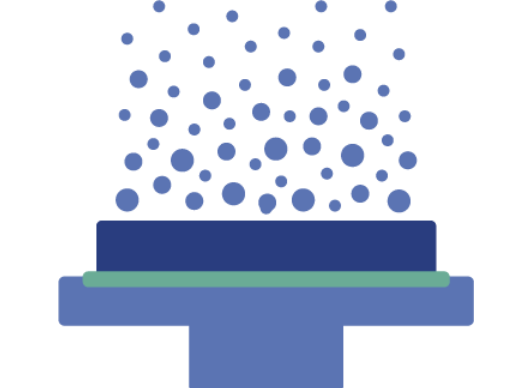

QC Water's transformation from recycled water to premium beverage ingredient happens through our state-of-the-art treatment process powered by Xylem technology, using carbon filtering, reverse osmosis and advanced oxidation (Ozone + Ultraviolet treatment).